Keiper PORUFLEX belts

Since we strive to guarantee the best possible properties for any application, we use premium raw materials from leading manufacturers to produce our PORUFLEX belts. They are available as round belts, V-belts and with special profiles and, thus, suitable for myriad power transmission and conveying applications.

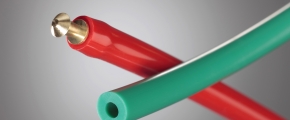

PU round belts

We have a complete range of polyurethane round belts for conveying and power transmission applications. PU round belts, available in open lengths, are extruded and homogeneous round profiles that can be welded for use as high-quality power transmission and conveying elements.

Our stock mainly comprises solid profiles with a smooth or slightly roughened surface and hollow profiles for nipple connections. Several types have FDA/USDA approval and comply with EU Directive 2007/19/EC. Although we generally produce in open lengths, we can also produce all belts according to your specifications. Our round belts convey a wide range of products such as foodstuffs, glass, roof tiles, PC boards and many more. The standard range of round belts is rounded off with aramid, polyester or glass-fiber reinforcements.

PU V-belts

PU V-belts run individually or alongside one another and convey products on slightly ascending or descending conveying systems without allowing the products being transported, e.g. boxes, tiles, glass slabs, cardboard articles etc., to slip. In addition, PU V-belts are used for driving live roller conveyors.

PU profile belts

PU profile belts are extruded homogeneously or processed subsequently to customize them for the intended application. We can change existing profiles into a large number of special profiles by means of various methods, e.g. notching, milling, polishing, cutting, welding and coating.

Our product range comprises numerous types of belts that have FDA/USDA approval and comply with EU Directive 2007/19/EC. Materials with different types of hardness also can be combined in one profile, depending on the intended purpose; usually this can only be achieved by means of a complex co-extrusion process.

By processing the standard profiles and selecting appropriate raw materials, we can produce an almost unlimited number of forms and types of belts. Therefore, new, high-quality customized profiles can be produced within a short time span, cost-effectively and even in small quantities.

Round hook belts

Round hook belts are the ideal solution for power transmission or conveying systems where several belts run on one shaft.

Since they are easy to install, downtimes and maintenance costs can be reduced significantly.

Endless extruded round belts

Our endless extruded round belts are ideal for low power requirements. They are elastic power transmission elements that do not need cost-intensive tensioning devices. In view of the special production process, they do not have any welding seams or terminal connections, which lets them run very smoothly. Moreover, they allow a minimum pulley diameter starting from 5.5 x belt diameter.

Endless turned round belts

Our endless turned round belts are wound either out of one homogeneous strand or one cord and spliced endlessly without thickening. For special applications, it would be possible to vulcanize the inner splice or to make a special splice based on our in-house engineering methods. This increases the tensile strength by up to 60%. In elastic types, the core is welded.